8MM, 12MM, 16MM, 24MM, 32MM, 44MM, 56MM Smart Feeder X Splice Sensor

| SIPLACE SmartFeeder | 4mm X SpliceSensor | 00141268 |

| SIPLACE SmartFeeder | 8mm X SpliceSensor | 00141270, 00141290, 00141370, 0014139000141500 |

| SIPLACE SmartFeeder | 2x8mm X SpliceSensor | 00141269, 00141289,00141479, 00141499 |

| SIPLACE SmartFeeder | 12mm X SpliceSensor | 00141271, 00141291, 00141371, 00141391 |

| SIPLACE SmartFeeder | 16mm X SpliceSensor | 00141272, 00141292, 00141372, 00141392 |

| SIPLACE SmartFeeder | 24mm X SpliceSensor | 00141273, 00141293 |

| SIPLACE SmartFeeder | 32mm X SpliceSensor | 00141274, 00141394 |

| SIPLACE SmartFeeder | 44mm X SpliceSensor | 00141275, 00141395 |

| SIPLACE SmartFeeder | 56mm X SpliceSensor | 00141276, 00141396 |

| SIPLACE SmartFeeder | 72mm X SpliceSensor | 00141277, 00141297 |

| SIPLACE SmartFeeder | 88mm X SpliceSensor | 00141278, 00141298 |

8MM - 00141500

12MM - 00141271

16MM - 00141392

24MM - 00141293

32MM - 00141374

32MM - 00141394

44MM - 00141395

56MM - 00141396

44MM - 00141375

56MM - 00141376

12MM - 00141391

00141397

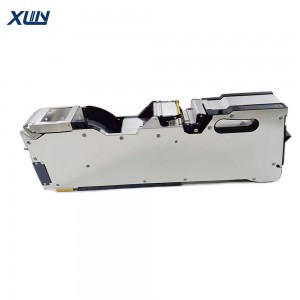

ASM SIPLACE (TX) is only 1m long and can accommodate 80 strip feeders x 8mm and 103,800 CPH at extreme speed, which is an unparalleled production giant.

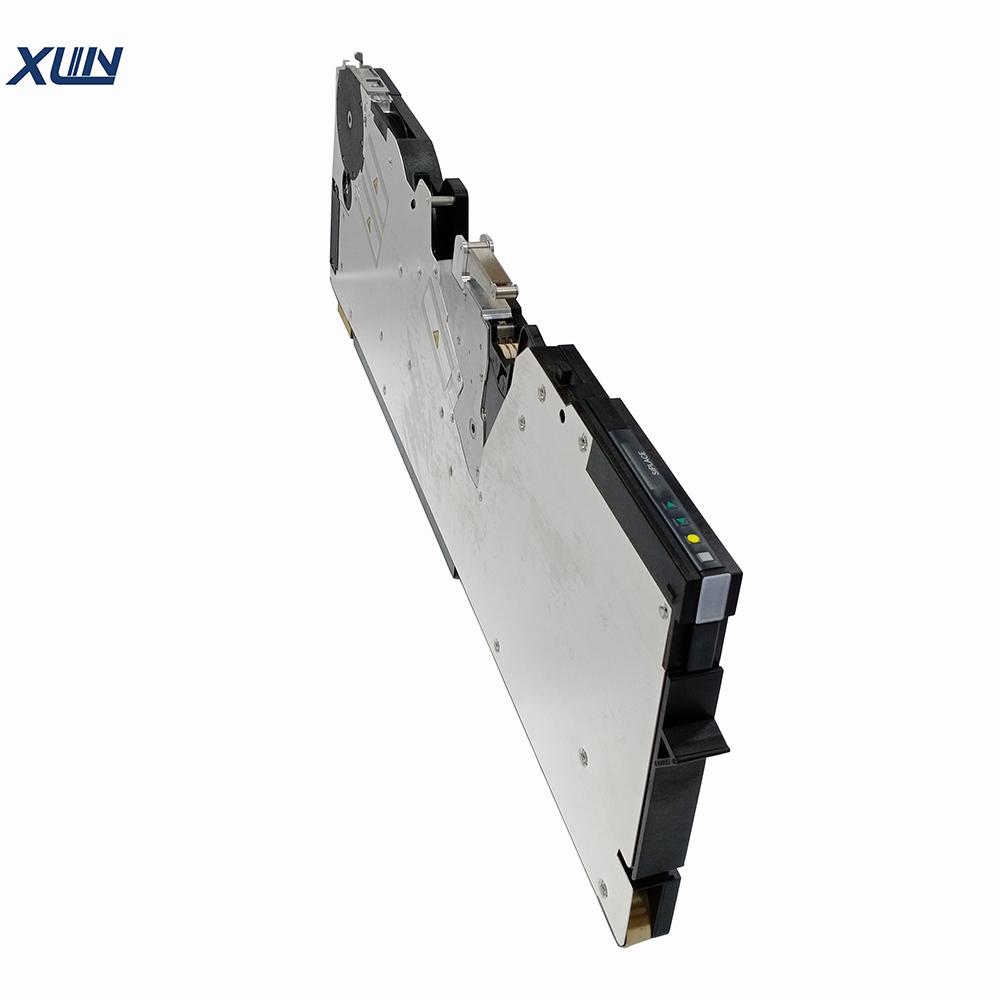

ASM SIPLACE (X) intelligent feeder with its exquisite German manufacturing technology and advanced software makes it free from calibration for life.

No carbon brush design of the loader greatly prolongs the service life of the feeder and loader. Moreover, it can automatically download the production program and automatically match the program to set the feeding parameters.

ASM SIPLACE (X) feeder has the world's only contactless power supply and data transmission. The feeder can be added and removed (plug and play) while the machine is running, and can be equipped with receiving sensor.

Profit from the advanced manufacturing process and technology of SIPLACE (X) intelligent feeder components and let SIPLACE series machine components to absorb well, mount better.

SMT Feeder, also called SMT Feeding Gun, Component Feeder, or Part Feeder, is and electric device to lock tape-and reel SMD components, peel off the tape(film) cover on the top of components, and feeds the uncovered components(by means of sprocket transmission) to the same fixed pickup position for pick up by pick-and-place machine.

SMT feeder is the most important part of SMT machine, and also an important part of SMT assembly that affects the PCB assembly capabilities and production efficiency.

Most components are supplied on paper or plastic tape, in tape reels that are loaded onto feeders mounted to the machine. Larger integrated circuits.(Ics) are sometimes

Supplied arranged in trays which are stacked in a compartment. More commonly Ics will be provided in tapes rather than trays or sticks, Improvements in feeder technology mean that tape format is becoming the preferred method of presenting parts on an SMT machine.