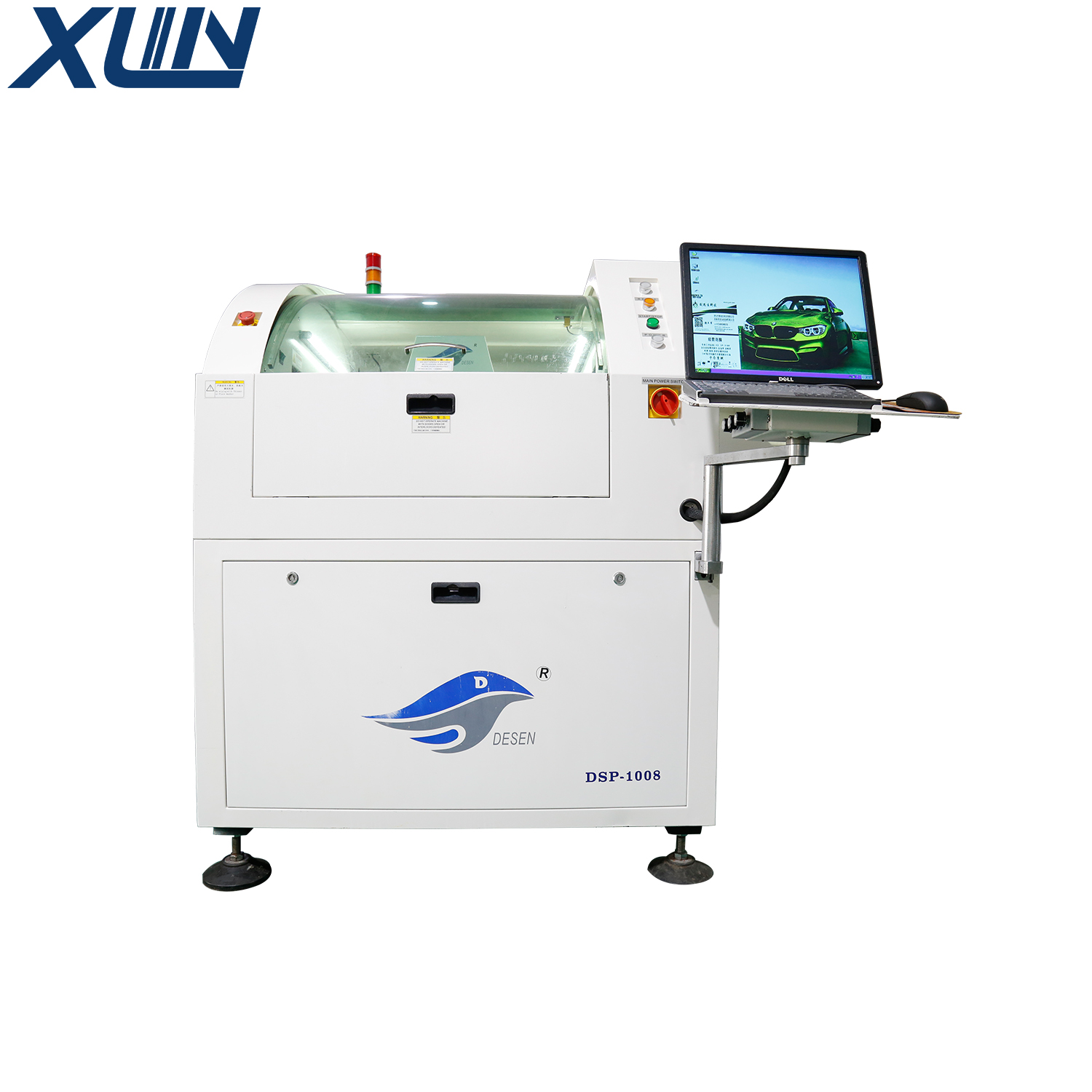

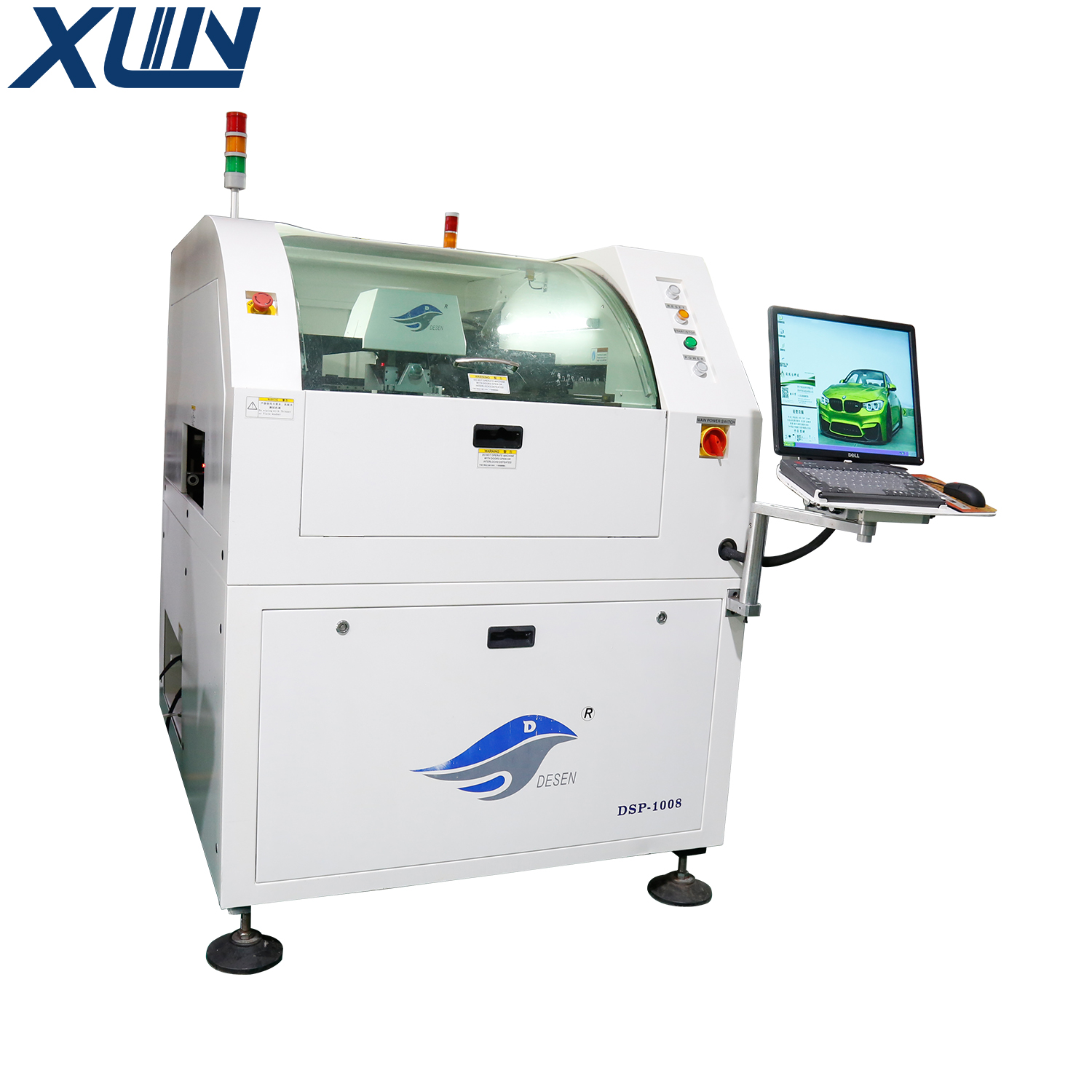

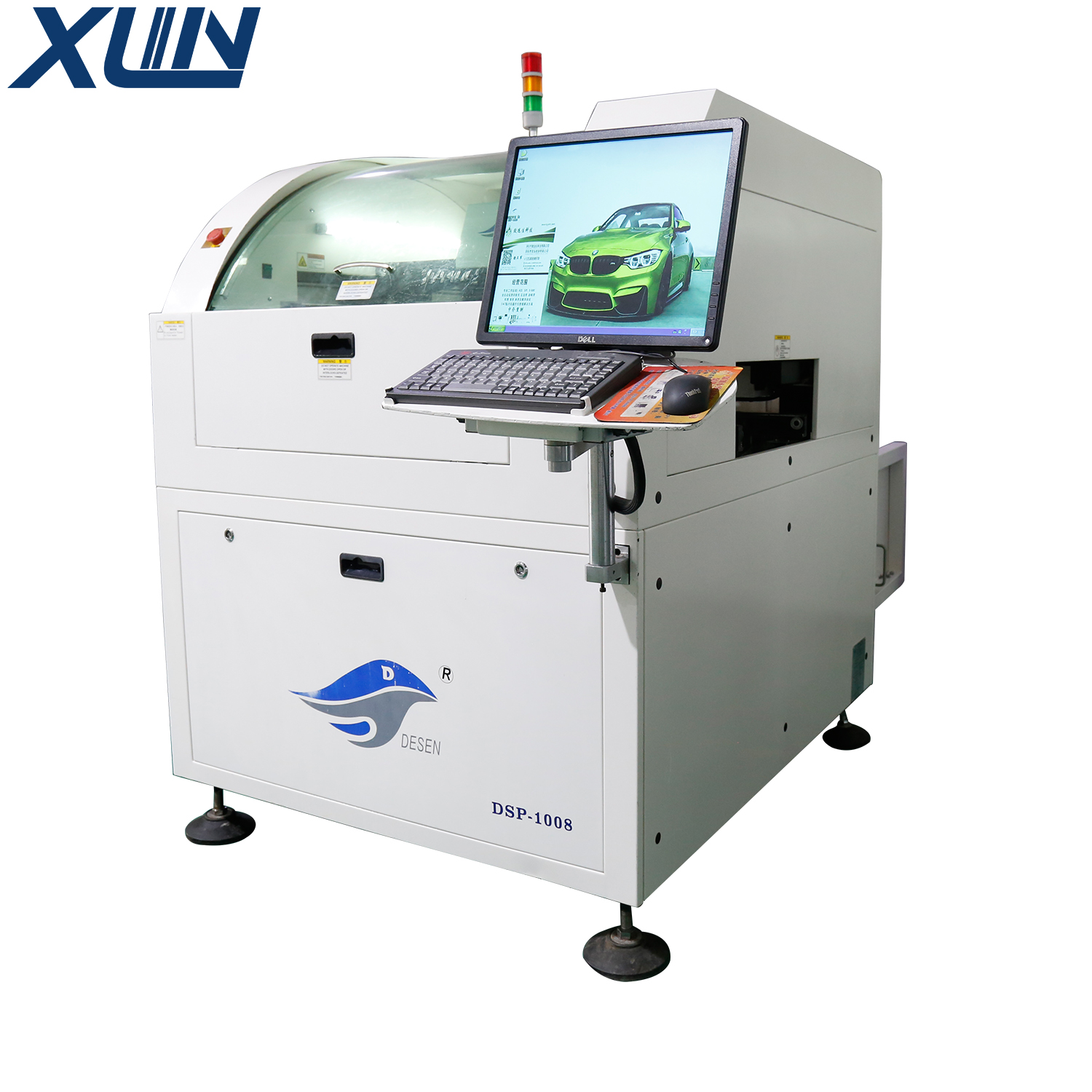

China Supplier 3d Aoi Machine - High Speed Full-Automatic PCB SMT Solder Paste Printer PCB SMT Stencil Printer – Xinling

China Supplier 3d Aoi Machine - High Speed Full-Automatic PCB SMT Solder Paste Printer PCB SMT Stencil Printer – Xinling Detail:

Modern solder paste printing machine is generally composed of plate loading, adding solder paste, embossing, circuit board transmission and so on. Its working principle is: first fix the circuit board to be printed on the printing positioning table, and then the left and right scrapers of the printer leak the solder paste or red glue to the corresponding pad through the steel mesh. The PCB with uniform missing print is input to the mounter through the transmission table for automatic mounting.

Operation steps of SMT automatic printer:

1. Check and start the equipment before operation according to the operating procedures;

2. Place the PCB (the PCB deformation cannot meet the requirements of production, and a supporting plate shall be added) on the loading frame;

3. Place the screen on the printing press according to the direction pointed by the screen arrow;

4. Select the corresponding printing program according to the produced products, enter * * mode for screen calibration, and debug the printing state;

5. Printing adjustment: adjust the printing speed, pressure and angle to make the amount of solder paste printed on the PCB pad uniform;

6. The first article shall be confirmed by the technician and mass production shall be carried out after it is qualified;

7. Every 30 printed boards shall be inspected by the inspector and sent to the mounter after passing the inspection;

8. After the operation, remove the screen board and clean it, shut down it according to the operating procedures, and clean the worktable.

Requirements for SMT automatic printer:

1. Wear rubber gloves or disposable gloves when operating the solder paste. If the solder paste is accidentally adhered to the skin, immediately clean it with alcohol and hand sanitizer, and then clean it with a large amount of water;

2. The remaining solder paste, used screen wiping paper and disposable gloves after operation shall be treated in accordance with the relevant provisions of environmental regulations;

3. Clean the equipment, tooling and tools before use, especially pay special attention to the environmental protection status on site before processing lead-free products.

PCB Parameters

Model DSP-1008

Maximum board size(X x Y) 400mm×340mm

Minimum board size 50mm×50mm

PCB thickness 0.4 – 5mm

Warpage ≤1%Diagonal

Maximum board weight 0-3kg

Board margin gap 20mm

Transfer speed 1500mm/s(Max)

Transfer height from the ground 900±40mm

Transfer orbit direction Left-Right,Right-Left,Left-Left,Right-Right

Transfer mode One stage orbit

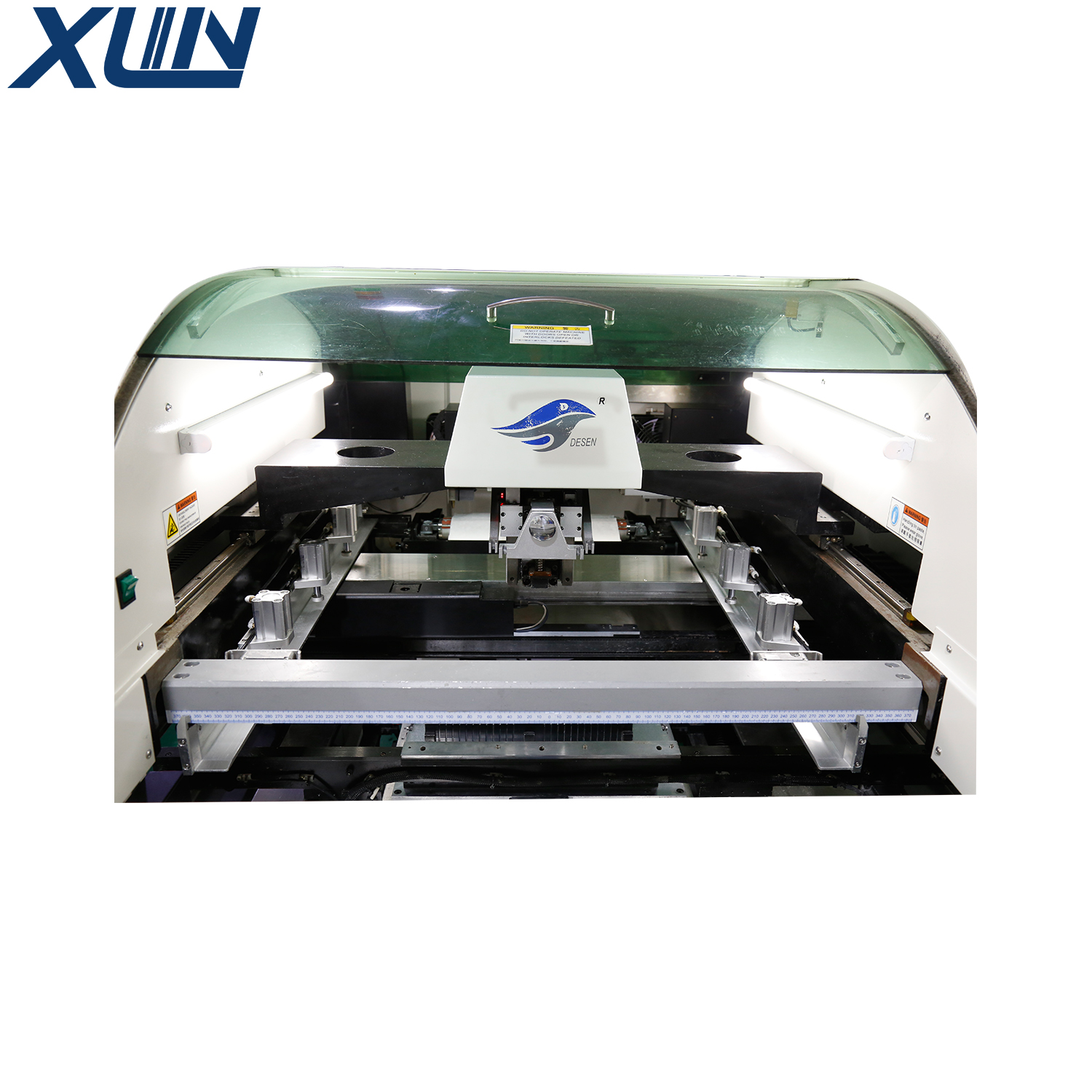

PCB damping method Programmable flexible side pressure + Adaptive PCB board thickness + Edge lock base clamp(Optional: 1. Multipoint partial vacuum of the bottom; 2. Edge locking and substrate clamping)

Support method Magnetic thimble, Equal high block,etc.(Optional:1.Vacuum Chamber;2.Special workpiece fixture)

Performance Parameters

Repetition precision of image calibration ±10.0μm @6 σ,Cpk ≥ 2.0

Repetition precision of printing ±20.0μm @6 σ,Cpk ≥ 2.0

Cycle time <7s(Exclude printing and cleaning)

Product changeover <5mins

Image Parameters

Field of view 8mm x 6mm

Platform adjustment range X:±5.0mm,Y:±7.0mm,θ:±2.0°

Benchmark point type Standard shape benchmark point(SMEMA standard),solder pad/openings

Camera system Independent camera,upwards/downwards imaging vision system

Printing Parameters

Printing head Floating intelligent printing head (two independent direct connected motors)

Template frame size 470mm x 370mm~737 mm x 737 mm

Maximum printing area(X x Y) 450mm x 350mm

Squeegee type Steel scraper/Glue scraper(Angel 45°/50°/60° matching the printing process)

Squeegee length 300mm(optional with length of 200mm-500mm)

Squeegee height 65±1mm

Squeegee thickness 0.25mm Diamond-like carbon coating

Printing mode Single or double scraper printing

Demoulding length 0.02 mm - 12 mm

Printing speed 0 ~ 200 mm/s

Printing pressure 0.5kg - 10Kg

Printing stroke ±200 mm (From the center)

Cleaning Parameters

Cleaning mode 1. Drip cleaning system; 2. Dry, wet and vacuum modes

Length of cleaning and wiping board 380mm(optional with 300mm, 450mm, 500mm)

Equipment

Power requirements 220±10%,60/60HZ-1¢

Compressed air requirements 4.5~6Kg/cm2

External dimension 1114mm(L)*1360mm(W)* 1500mm(H)

Product detail pictures:

Related Product Guide:

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for China Supplier 3d Aoi Machine - High Speed Full-Automatic PCB SMT Solder Paste Printer PCB SMT Stencil Printer – Xinling , The product will supply to all over the world, such as: Kuala Lumpur, Norwegian, Swansea, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.