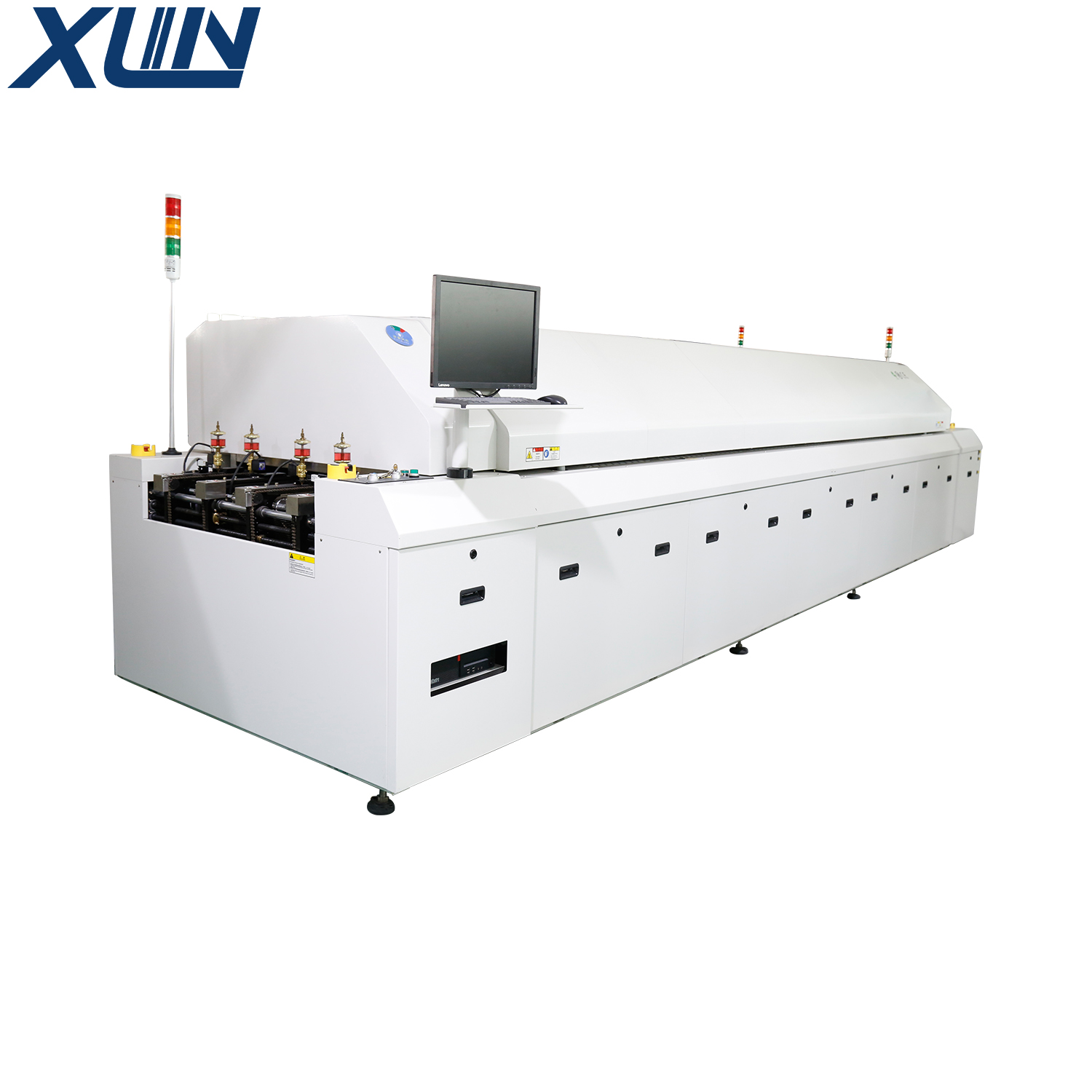

JT Professional PCB Reflow Oven Soldering Machine Tea-1000d

Model X8-TEA-1000D

Machine parameters

Dimension(L*W*H) 6000*1660*1530mm

Weight Approx 2955kgs

Number of heating zone top 10/bottom 10

Length of heating zone 3895mm

Number of cooling zone top 3/bottom 3

Rectifying plate structure Small circulation

Exhaust volume requiement 10m³/min*2(Exhausts)

Color Computer grey

Control system

Power supply requiement 3 phase ,380v 50/60HZ(Option:3 phase ,220v 50/60HZ

Total power 83 KW

Startup power 38 KW

Normal power consumption 11 KW

Warming time Approx:20min

Temperature control range Room Temperature -300ºC

Temperature control method PID close loop control + SSR driving

Temperature control precision ±1ºC

Temperature deviation on PCB ±1.5ºC(by RM board test standard)

Data storage Process data and status storage

Abnormal alarm Abnormal temperature(extra-high/extra low temperature after constant temperature)

Board dropped alarm Singal light(yellow-warning;green normal;red -Abnormal

Conveyor system

Rails structure Overall sectional type

Chain structure Double buckle for preventing board jammed

Max width of PCB 400mm(option:460mm) dual-rail 300mm*2

Range of rail width 50-400mm(option:50-460mm) dual-rail 300mm*2

Component height Top 30/Bottom 30mm

Conveyor direction L→R(option:R→L)

Conveyor rail fixed type Front rail fixed(option: Rear rail fixed)

PCB conveyor direction Air-reflow=chain+mesh(N2-reflow=chain option:mesh)

Conveyor height 900±20mm

Conveyor speed 300-2000mm/min

Auto-lubrication Multi-lubricating mode can be chosen

Cooling system

Cooling method Firced air Water chiller