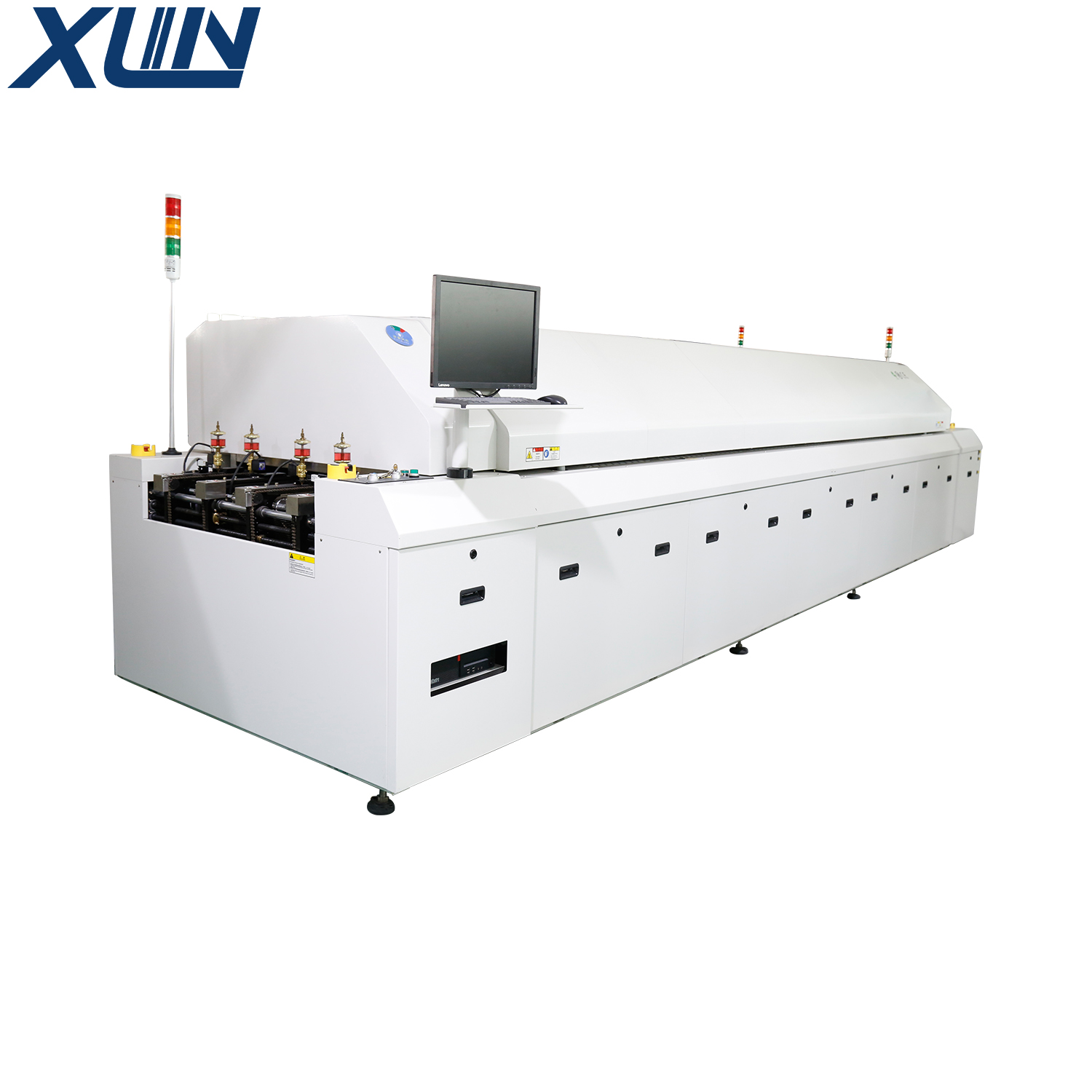

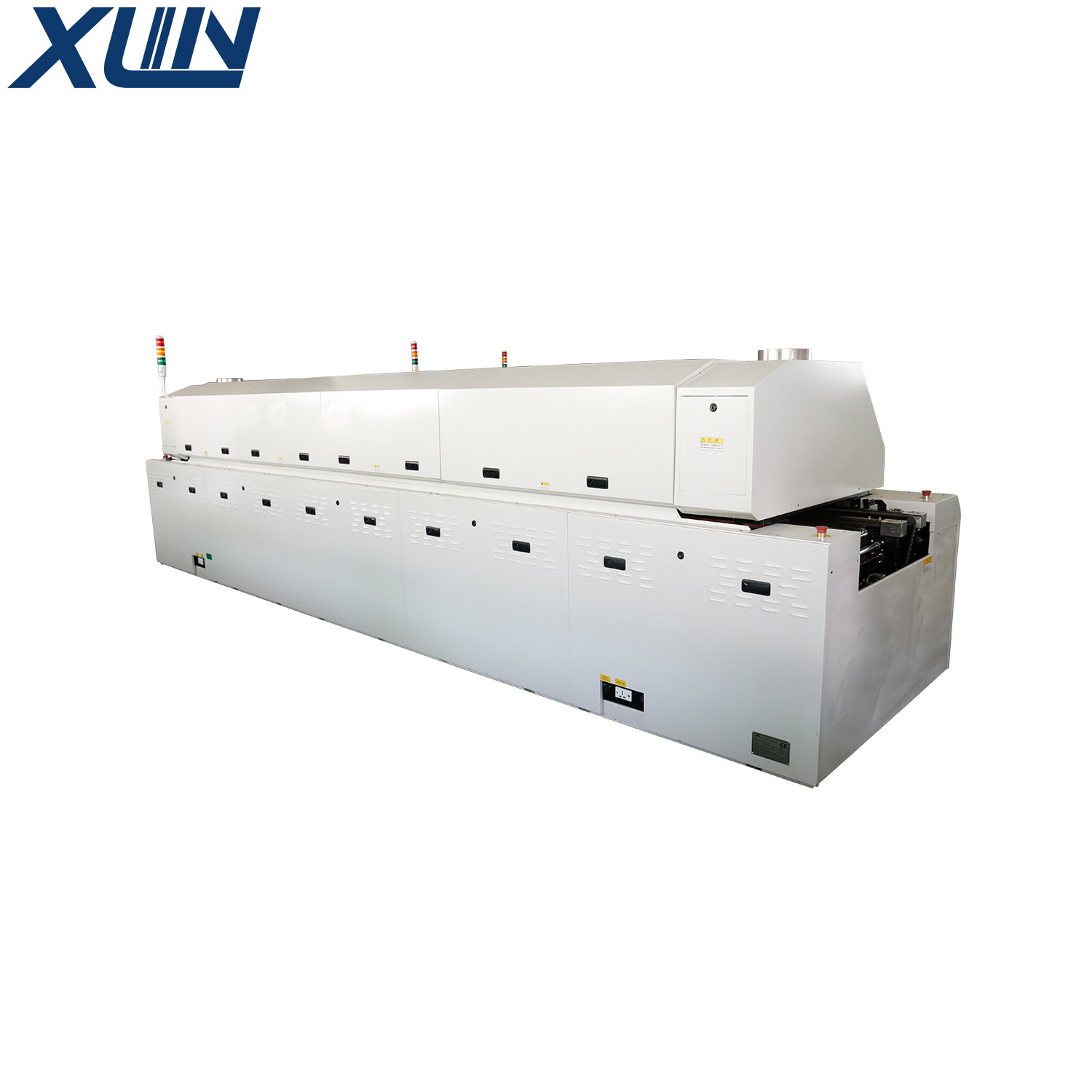

JT Professional PCB Reflow Oven Soldering Machine Tea-1000d – Xinling

JT Professional PCB Reflow Oven Soldering Machine Tea-1000d – Xinling Detail:

Model X8-TEA-1000D

Machine parameters

Dimension(L*W*H) 6000*1660*1530mm

Weight Approx 2955kgs

Number of heating zone top 10/bottom 10

Length of heating zone 3895mm

Number of cooling zone top 3/bottom 3

Rectifying plate structure Small circulation

Exhaust volume requiement 10m³/min*2(Exhausts)

Color Computer grey

Control system

Power supply requiement 3 phase ,380v 50/60HZ(Option:3 phase ,220v 50/60HZ

Total power 83 KW

Startup power 38 KW

Normal power consumption 11 KW

Warming time Approx:20min

Temperature control range Room Temperature -300ºC

Temperature control method PID close loop control + SSR driving

Temperature control precision ±1ºC

Temperature deviation on PCB ±1.5ºC(by RM board test standard)

Data storage Process data and status storage

Abnormal alarm Abnormal temperature(extra-high/extra low temperature after constant temperature)

Board dropped alarm Singal light(yellow-warning;green normal;red -Abnormal

Conveyor system

Rails structure Overall sectional type

Chain structure Double buckle for preventing board jammed

Max width of PCB 400mm(option:460mm) dual-rail 300mm*2

Range of rail width 50-400mm(option:50-460mm) dual-rail 300mm*2

Component height Top 30/Bottom 30mm

Conveyor direction L→R(option:R→L)

Conveyor rail fixed type Front rail fixed(option: Rear rail fixed)

PCB conveyor direction Air-reflow=chain+mesh(N2-reflow=chain option:mesh)

Conveyor height 900±20mm

Conveyor speed 300-2000mm/min

Auto-lubrication Multi-lubricating mode can be chosen

Cooling system

Cooling method Firced air Water chiller

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for JT Professional PCB Reflow Oven Soldering Machine Tea-1000d – Xinling , The product will supply to all over the world, such as: South Korea, Kuwait, Jamaica, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!