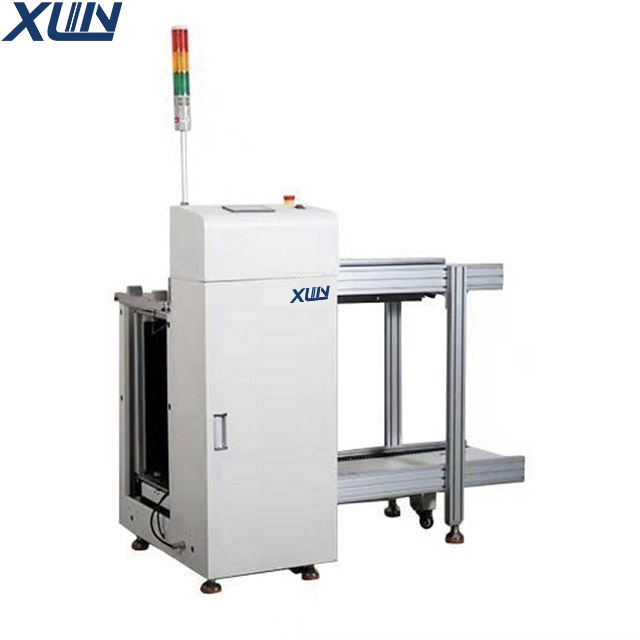

Original Factory Pick And Place Project - SMT Handing LED PCB Buffer Conveyor for SMT Production Line – Xinling

Original Factory Pick And Place Project - SMT Handing LED PCB Buffer Conveyor for SMT Production Line – Xinling Detail:

PCB chain conveyor :

1- Max rail width:400mm (option: 350-600mm)

2-Chain conveyor , It is suitable for heavy pcb or coating line

3-Lid is optional

4-0.5/0.6/1.0/1.2m lenght is opional

5-1.0 /1.2m for 2 segment is optinal

Model X-B10

Automatic produciton line Assembly

Automation Automation

Rhythm Flow production line

PCB transport height 920+20mm

The thickness of the PCB 0.6-6mm

Control system PPLC+Touch Screen

Transport package wooden packing

Transmission type Flexible

Certification CE. ISO. RoHS

PCB size 50*50 – 300*450mm

PCB Capacity 25pcs

Specification 1500*902*1636mm

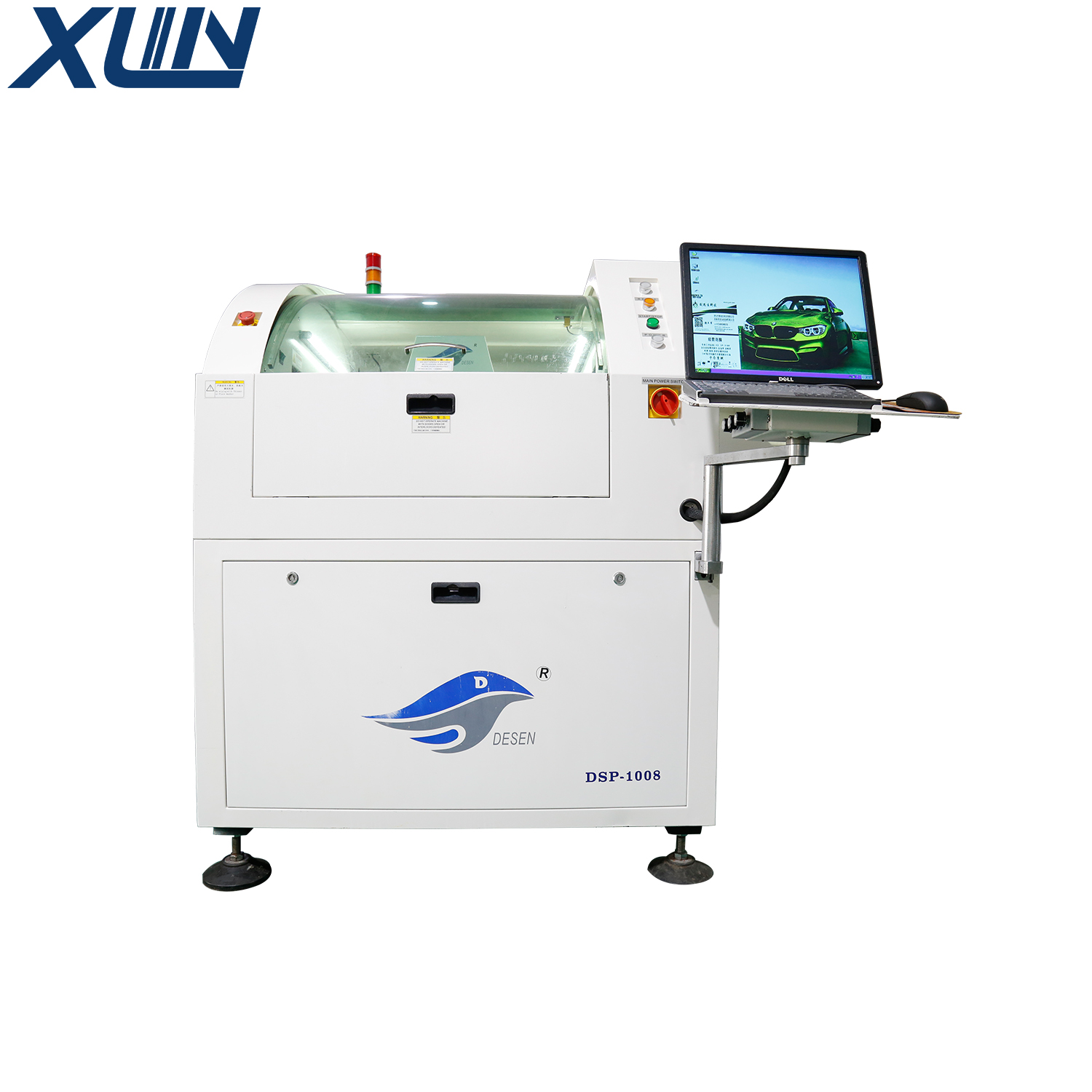

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing support of consumer for Original Factory Pick And Place Project - SMT Handing LED PCB Buffer Conveyor for SMT Production Line – Xinling , The product will supply to all over the world, such as: Lesotho, Oslo, Panama, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.